Reliable machines

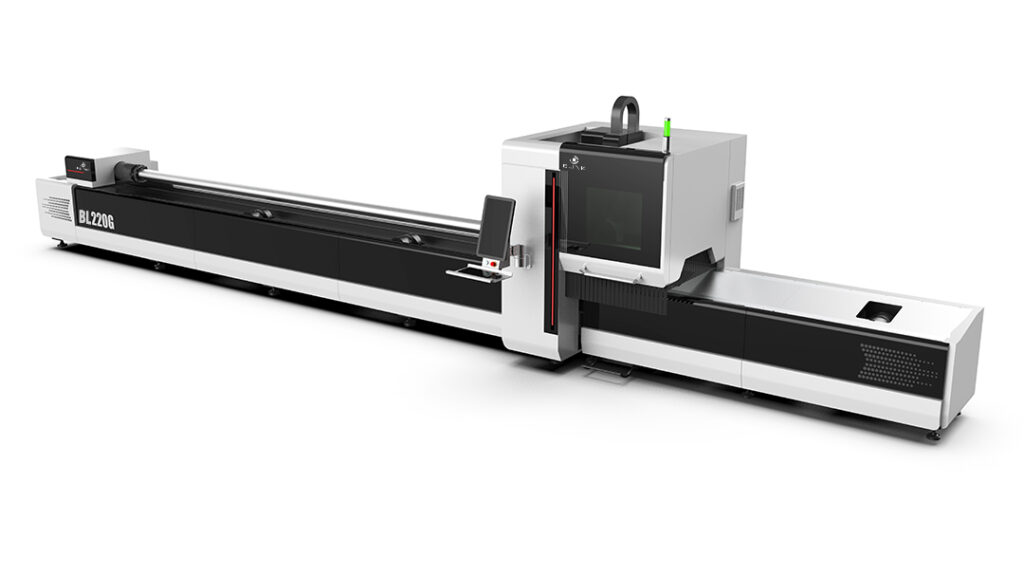

Laser Cutting Machines

Fiber laser cutters are the ultimate in high-power, precision cutting of metal materials. With advanced fiber laser sources starting at 1.5 kW and going up to 12 kW, BLINK laser cutters deliver exceptional performance. These powerful machines are ideal for cutting mild and stainless steel up to 30 mm thick, and aluminum up to 25 mm thick.

Why choose BLINK laser cutters?

- Speed: Fiber laser cutting at speeds up to 10 m/min.

- Precision: Accuracy up to 0.05 mm.

- High quality cutting: Cut surface ready for welding without additional grinding.

- Reliability: Full service, service and technical support.

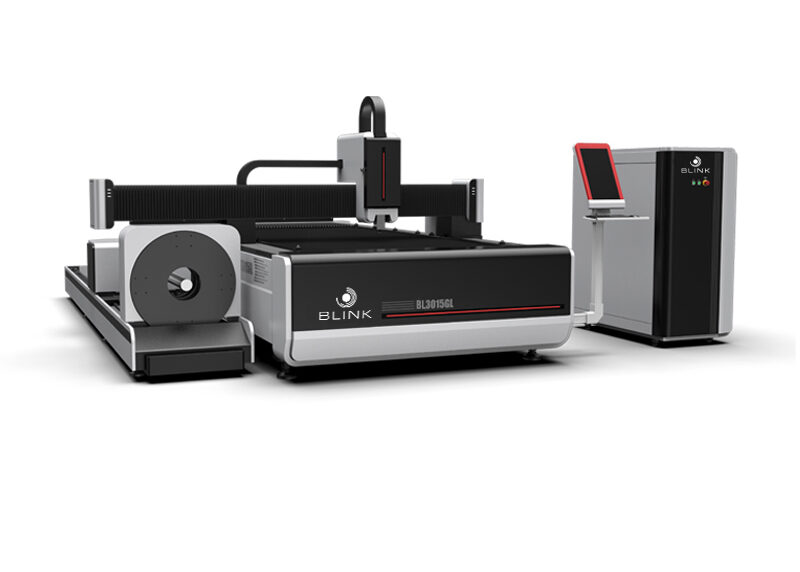

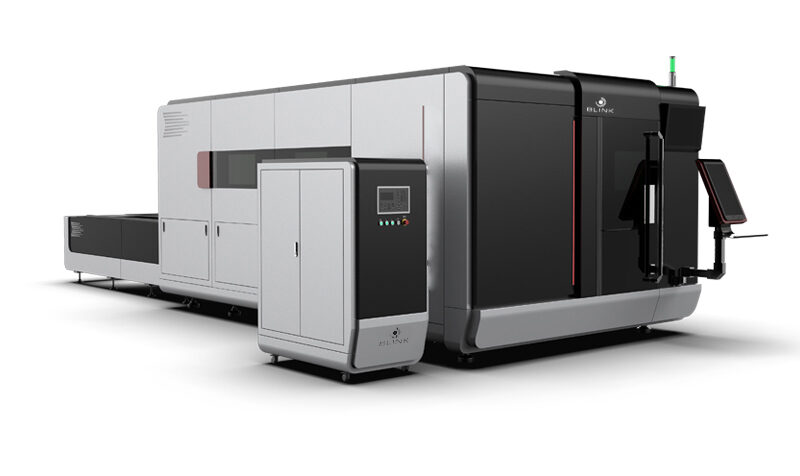

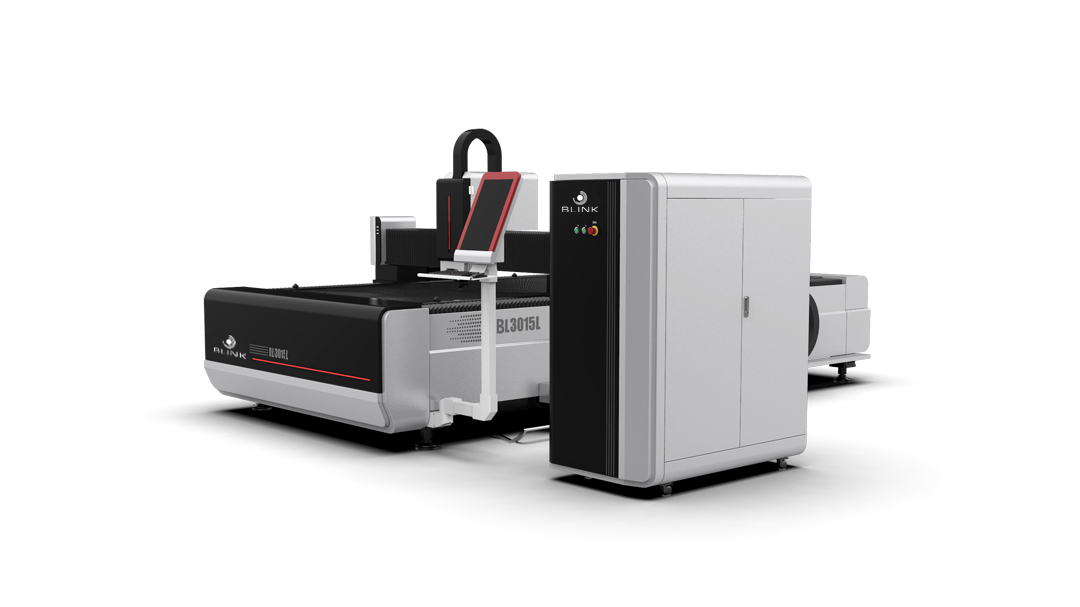

BLINK Laser Cutter

BLINK laser cutting machines are widely used in various industries such as:

- Shipbuilding

- Aerospace

- Military products

- Medical machines

- Computer cases

- Non-ferrous metal processing and marking

Thanks to their versatility, our fiber laser cutting machines are the ideal solution for many industries.

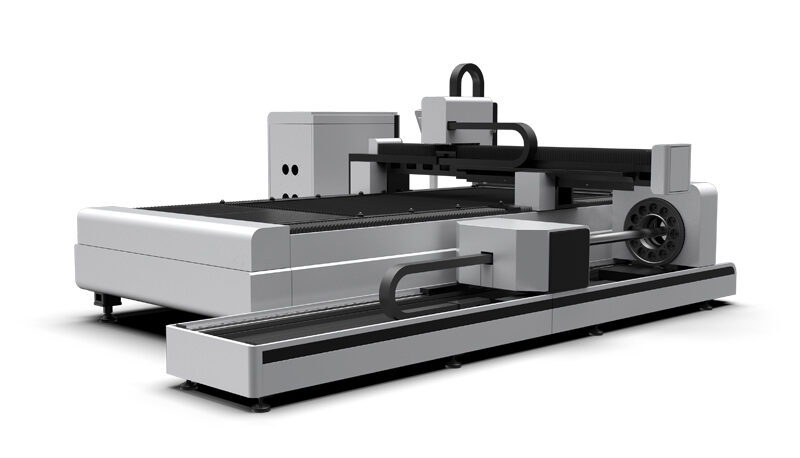

Ergonomic design

| Thickness of Cut Materials | ||||||

|---|---|---|---|---|---|---|

| Material | Cutter Power | |||||

| 1500W | 2000W | 3000W | 6000W | 8000W | 12000W | |

| Stainless Steel | up to 5mm | up to 6mm | up to 8mm | up to 16mm | up to 25mm | up to 25mm |

| Carbon Steel | up to 12mm | up to 16mm | up to 20mm | up to 22mm | up to 25mm | up to 25mm |

| Galvanized Steel | up to 5mm | up to 6mm | up to 8mm | up to 16mm | up to 25mm | up to 25mm |

| Aluminum | up to 3mm | up to 4mm | up to 6mm | up to 12mm | up to 25mm | up to 25mm |

| Brass | up to 2mm | up to 4mm | up to 5mm | up to 10mm | up to 12mm | up to 12mm |

Intuitive operating system

All BLINK laser cutters are equipped with a built-in Windows-based computer system with an intuitive, durable control panel. This is especially useful in difficult conditions. The operating system is available in Polish. A large touch screen, intuitive and easy-to-use menu allows easy parameter changes and reading of current data.

Cutting precision

Laser cutting machines for metal processing

If you process metal, laser cutters are the best choice. BLINK fiber laser cutting is characterized by a speed of up to 10 m/min, which is much better than in the case of traditional plasma cutters. Thanks to small deformations and a smooth cutting table, our laser cutters provide excellent cutting quality.

Podstawowe parametry wycinarek laserowych BLINK

| Laser Type | FIBER | |||||

|---|---|---|---|---|---|---|

| Laser Power | 1500W | 2000W | 3000W | 6000W | 8000W | 12000W |

| Wavelength | 1080nm | |||||

| Control System | Cypcut Controller | |||||

| Positioning | Red Laser Dot | |||||

| Electrical Voltage | 380V/3P | 380V/3P | 380V/3P | 380V/3P | 380V/3P | 380V/3P |

| Power Frequency | 50/60Hz | |||||

| Electric Current | 26.5A | 29.2A | 38.1A | 60.7A | 75.7A | 95.2A |

| Max Power Consumption | 14kW | 15.4kW | 20.1kW | 32kW | 39.8kW | 50kW |

| Focal Length | 125mm/150mm/200mm | |||||

| Cooling System | Industrial Chilled Water Unit | |||||

Cooling system

Our fiber laser sources are water-cooled, so our machines are supplied with a robust and efficient water chiller to ensure reliable operation 24/7.

Design

The Japanese Fuji servo motor is transmitted to the drive shaft through a precision gear motor from France (backlash less than 3 arc min), which effectively ensures the reliability of the transmission accuracy. The double positioning of the guide rail and the rack makes the machine more precise and stable. The three-axis dust covers provide good protection to the rails and racks, making the machine cleaner and longer service life

Laser cutting machines - purpose

The BLINK laser cutter is designed for professional use in factories and industrial plants where cutting accuracy, quality and speed of work are required.

Main advantages

no thermal damage

high cutting speed and efficiency

intelligent operating software

easy maintenance of the device

Laser head

BLINK laser cutting machine has a laser head configured with auto focus to provide flexible, fast and collision-free cutting, automatically recognizes the edge and saves material.

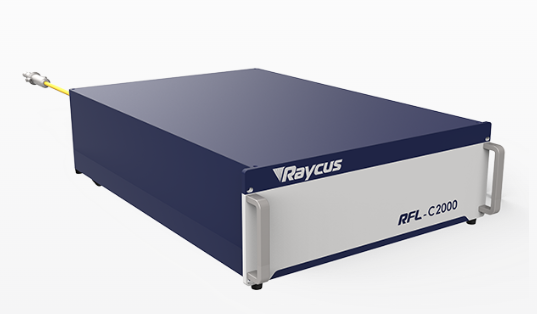

Laser source in BLINK cutting machines

All BLINK cutting machines are equipped with a Raycus fiber laser source. The Raycus laser is one of the best available laser sources of this type in the world. The Fiber Laser is a guarantee of long-term and failure-free operation. Thanks to this technology, labor and production costs can be significantly reduced, due to very low operating and maintenance costs.

Laser cutters are technologically advanced machines that use a laser to precisely cut various types of materials, primarily metals and plastics. In our offer, you will find fiber laser cutters – metal lasers, which are an ideal solution for manufacturing companies, enabling material cutting according to individual customer needs. Laser cutting technology ensures high quality and accuracy, minimizing waste and allowing for efficient processing of sheet metal or cutting pipes effectively.Thanks to the use of fiber lasers in laser cutters, it is possible to achieve very high precision and accuracy when cutting materials. Laser technology also allows for fast cutting, increasing processing efficiency. The laser head is controlled by CNC, enabling automation of the process and precise cutting according to specified profiles. Both the laser plotter and the worktable ensure maximum stability and efficiency in cutting and engraving various materials.Laser cutters are versatile tools for material processing in a fast, precise, and efficient way. A laser machining tool is essential in industries where high quality and cutting accuracy matter. Fiber lasers allow cutting of metal sheets, sheet metal, metals, and plastics.