Reliable machines

Laser welders

Modern professional BLINK laser welding machines are the highest quality and repeatability of welding. Welding lasers have the ability to join materials of different types, shapes and thicknesses. Laser welding is characterized by speed (welding speed up to 4 times faster than TIG method) and incredible ease of making aesthetic and quality welds.

Thanks to the use of an efficient and high-performance laser source, the welded joint is durable and deformation is negligible (much less than with other methods). BLINK is a device equipped with a fiber laser. These devices have a laser with stepless power adjustment so that we can perfectly select its parameters, so that the welding is of the highest quality.

In our offer we have all the consumable parts for our welding machines.

BLINK handheld laser welder

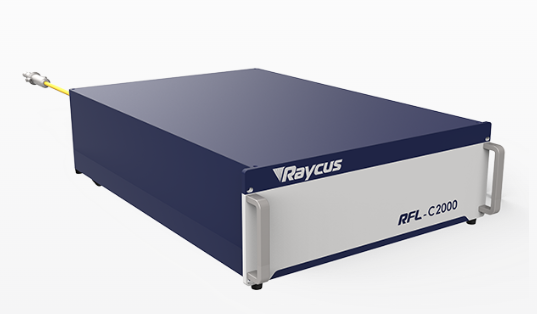

BLINK laser welders are professional industrial welding machines, which come in several basic power variants: 1000W, 1500W, 2000W, 3000W. All BLINK welders have a very durable and best quality RAYCUS laser source bundled with a dedicated very robust and convenient woobleBLINK moving beam head. A BLINKwire automatic wire feeder is included with all BLINK professional welding machines.

The BLINK laser welder is a versatile and indispensable device in welding where welding speed and ease of use, especially in industry, is the key to success. The operator can be easily trained in welding at our site or at the customer’s site.

Ergonomic design

Basic parameters of BLINK handheld laser welding machines

| Parameter | weldBLINK1000 | weldBLINK1500 | weldBLINK2000 | weldBLINK3000 |

|---|---|---|---|---|

| Laser type | FIBER | |||

| Max power output | 1000W | 1500W | 2000W | 3000W |

| Wavelength | 1070nm | |||

| Mode of operation | Continuous/Modulated | |||

| Positioning | Laser red dot | |||

| Electrical voltage | 230V | 230V | 230V/380V | 380V |

| Frequency (power supply?) | 50/60Hz | |||

| Safety | 25A | 32A | 32A | 40A |

| Max power consumption | 5kW | 7kW | 9kW | 11kW |

| Focal length | 150mm | |||

| Cooling system | Industrial chiller | |||

| Automatic wire feeder | Yes, included | |||

| Grubość drutu (spoiwa) | 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm | |||

Hand-held laser welding machine - purpose

BLINK laser welder is designed for professional use in factories and industrial plants where quality and speed of welds are required.

Main advantages

machine very easy to operate, after a short training practically anyone can weld

high efficiency and speed of welding (up to 4 times faster than TIG method!)

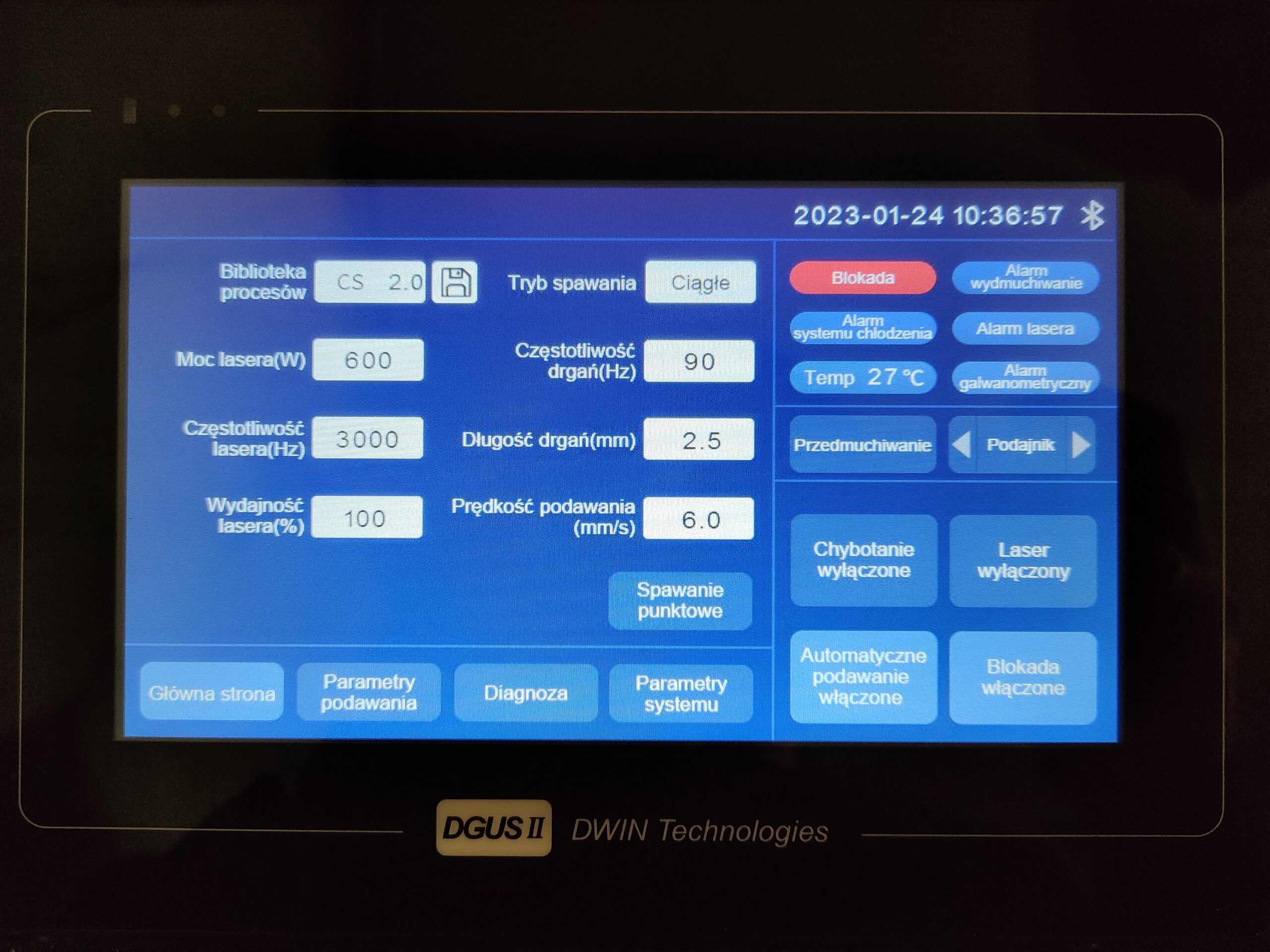

touch intuitive control panel in Polish language

The possibility of welding with filler (wire) and without filler (wire),

Welded materials

stainless and acid resistant steel

aluminum

titanium

black steel

copper

gold

silver

and many other materials

Approximate thicknesses of welded materials

| Thickness of welded materials | |||

|---|---|---|---|

| Material | Welding power | ||

| 1000W | 1500W | 2000W | |

| Stainless steel | up to 3mm | up to 4mm | up to 5mm |

| Carbon steel (black) | up to 3mm | up to 4mm | up to 5mm |

| Galvanized steel | up to 2.5cm | up to 3mm | up to 4mm |

| Aluminum | up to 2mm | up to 3mm | up to 4mm |

| Brass | up to 1mm | up to 1.5mm | up to 2mm |

BLINKBLINK

Construction of the laser head

The handheld laser welder is equipped with a modern woobleBLINK laser head with an electric moving beam (oscillation) system. For safety and life, the entire head is liquid-cooled, which allows continuous operation and welding even in the most demanding conditions. All heads in our welders are equipped with WOOBLE function. The WOOBLE function with a moving lens controlled automatically allows us to correct imperfections in the material giving us faster speed and better quality welding. In addition, the variable spot type (beam width up to 5mm) allows better weld selection depending on the position and type of welding (butt, circular, internal and external angles of the materials to be joined). Copper nozzles facilitate laser welding, during which the operator can easily rearm the device to use wire (steel, stainless steel or aluminum).

Types of welding marks

Spot

Line

Circle

Triangle

Eight

Double Circle

Operating system and driver in BLINK lasers

The operating system of BLINK laser welding machines is available in Polish. The large touch-screen display, intuitive and easy-to-use menu allows easy changes of parameters and reading of current data. The system allows you to save specific parameters for different types of welded materials and their thickness.

Intuitive touch panel

Raycus laser source

All BLINK welders are equipped with a fiber optic laser source from Raycus. The Raycus laser is one of the best available fiber laser sources in the world. It guarantees long-lasting and trouble-free stable operation. The approximate working life of the fiber source is 100,000 working hours, which is about 45 years of operation. It is a friendly and safe technology for the workplace and the environment. With this technology, labor and production costs can be significantly reduced due to very low operation and maintenance costs. The fiber laser beam can weld many types of materials such as copper, brass and aluminum.